YC – YR Product Systems

These are systems designed for making high performance flooring, electric poles, traffic light poles, gas cylinder

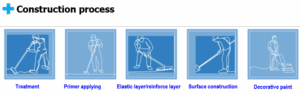

1. Construction process

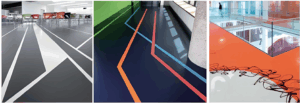

2. Application scenarios

Requirements for limits on hazardous substances in floor covering materials (Type S)

| No. | Criteria | Limit |

| 1 | Volatile Organic Content (VOC> (g/L) | ≤ 120 |

| 2 | Free formaldehyde content (mg/kg) | ≤ 100 |

| 3 | Total benzene, toluene, ethylbenzene, xylene (g/kg) | ≤ 5 |

| 4 | Free Diisoamioester (TDI, HDI) limit on type of polyurethane (g/Kg) | ≤ 2 |

| 5 | Total ether glycol and ester, ether contents (mg/kg) | ≤ 300 |

| 6 | Free 4,4-diaminodiphenylmethane content (g/kg) | ≤ 10 |

| 7 | Soluble heavy metals (mg/kg) | |

| Lead(Pb) | ≤ 30 | |

| Cadmium (Cd) | ≤ 30 | |

| Chromium (Cr) | ≤ 30 | |

| Mercury (Hg) | ≤ 10 | |

| 8 | Total volatile organic content(TVOC), Emmision (mg/m) | ≤ 10 |

| 9 | Formaldehyde emmision (mg/m) | ≤ 0.1 |

| Physical Properties | |

| Compression deformation rate (%) | 4.5~5.0 |

| Oil resistance (%) | < 4.3 |

| Resistance value (108 W) | > 8.0 |

| Tensile strength (MPa) | > 4.9 |

| Breaking elongation (%) | > 300 |

| After Aging | |

| Tensile strength (MPa) | > 5.0 |

| Breaking elongation (%) | > 500 |

| Static stiffness before durability (kN/mm) | 20~25 |

| Joint stiffness before durability test (kN/mm) | 25~28 |

| Static stiffness variation after durability test (%) | ≤20 |

| Join stiffness variation after durability test (%) | ≤20 |

| Sample thickness change after durability (%) | ≤10 |

| Physical Properties | |

| Appearance (A/B) | Amber/Brown |

| Viscosity at 25°C (A/B)(mPa.s) | 650±150/200±50 |

| Hardness (Shore D) | 86±5 |

| Density (g/cm3) | (1.20±0.1 |

| Elonggation at break (%) | (5±0.5) |

| Tensile strength (MPa) | 70±10 |

| Tensile modulus (MPa) | 3500±500 |

| Bending strength (MPa) | 90±10 |

| Flexural modulus (MPa) | 1800±200 |

| Temperature tolerance range | -30°C~80°C |

| Operational time | 30~60min |

Advantages of synthetic PU materials